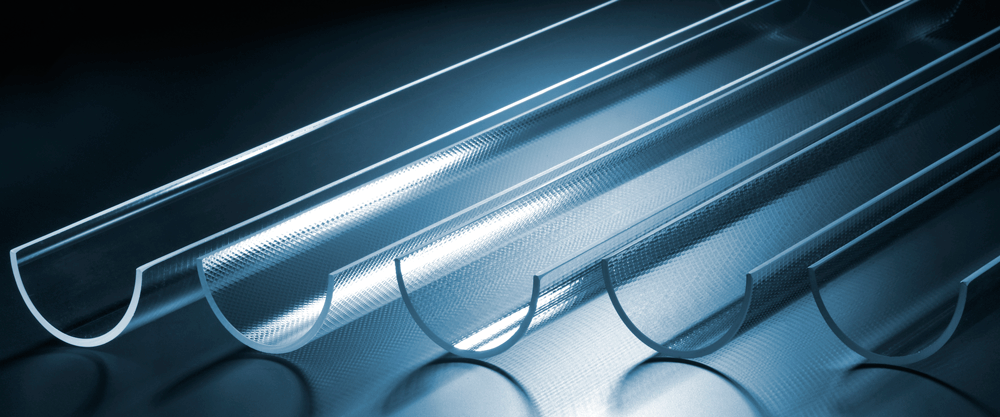

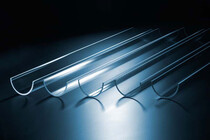

Glass half-shells for high requirements

Borosilicate glass is generally characterized by a very small coefficient of thermal expansion and by a high thermal shock resistance. The coefficient of expansion of the finished products is so low that there is hardly any tension in the material and the glass part, for example, does not crack in the event of a sudden heat input.

This enables us to produce half-shells in our company, which are mainly used for applications in the area of thermally stressed covers for light sources, for light refraction or generally for covering parts or assemblies. For high-temperature loads (for example halogen lamps), we recommend quartz glass as a raw material. The half-shells are formed by forming or by glass cutting of pipe material.

If necessary, the half-shells can also be provided with microstructures on the surface by ultrasonic processing (ultrasound).