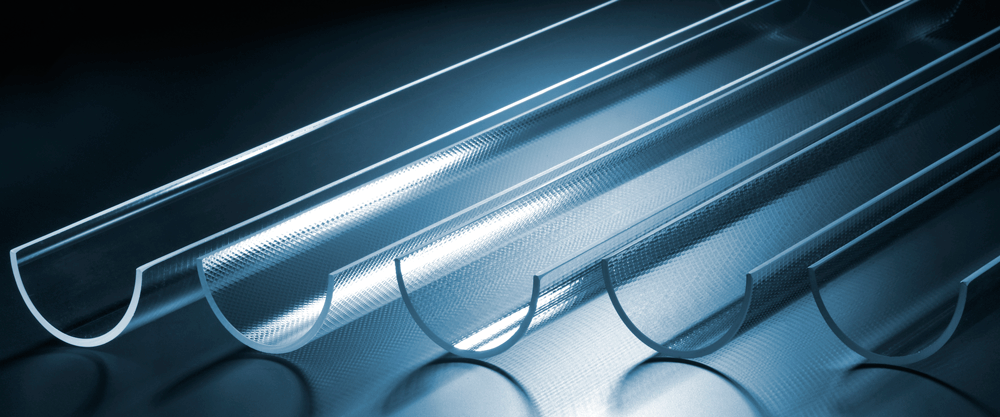

Calibrated glass tubes

For precision glass tubes, there are a wide range of applications in the production and process technology of numerous industries. Applications can be found in the fields of biotechnology, chemistry, electrical engineering, instrumentation and apparatus engineering, mechatronics, laboratory technology and mechanical engineering. The glass tubes made of borosilicate glass are nowadays e.g. In the laboratory area. The special composition of the glass allows extremely high chemical resistance, minimal thermal expansion as well as a high thermal shock resistance.

Applications that are subject to high quality specifications require a high degree of quality assurance and quality control in every step. Our experienced staff and our own quality management guarantee the fulfillment of high and individual quality requirements. Through our own production of the tools, a consistent quality of the products is ensured.

With the help of special tools, we produce glass products with high-precision internal diameters, mainly made of borosilicate glass 3.3, by calibration of glass tubes. Here, we can manufacture precision glass tubes in the diameter range from 0.4 - 250 mm and with micrometer dimensions in accordance with the individual customer requirements.

In addition to the tight tolerances of the calibrated precision glass tubes, we offer a variety of other processing options for calibrated glass tubes, for example on the pipe ends or on the glass surface, in order to adapt the finished tubes and rods to your individual requirements.

Special shapes with square, oval or conical internal geometries are also possible. Printed or unprinted in various processing stages, these products are used, for example, as injection cylinders, measuring glasses, rotameters or laser tubes.